Aircraft engine maintenance lives and dies by inspection quality. Spotting a defect is only the first step. Maintenance teams also need to understand what they are looking at, how severe it is, and whether it is changing over time. That is where measurement-focused videoscopes have become a serious advantage, especially for operators trying to reduce unnecessary teardowns while still protecting reliability.

Tools like the USA3000J-6, offered by USA Borescopes, are built for inspection environments where access is limited, surfaces are complex, and decisions need to be backed by repeatable evidence. Dual view imaging paired with 3D measurement capability helps technicians move beyond best guesses and toward consistent, defensible findings.

Dual View, Explained in Maintenance Terms

Dual view is easiest to understand when you picture the real-world problem it solves. In many engine sections, a single camera viewpoint can make a feature look smaller, larger, deeper, or shallower than it truly is. Angle, curvature, and lighting can all distort perception, especially on reflective alloys.

With dual view, technicians can see the same area from two directions, typically a forward view and a side view. That second perspective is not just convenient. It is a practical check against false impressions. A suspected nick on a blade edge can look dramatic from one angle and far less significant from another. Dual view helps validate what is real and what is an artifact of viewing geometry.

For aircraft maintenance teams, that validation can reduce re-inspections, shorten back-and-forth reviews, and improve confidence when deciding whether to continue monitoring a condition or take corrective action.

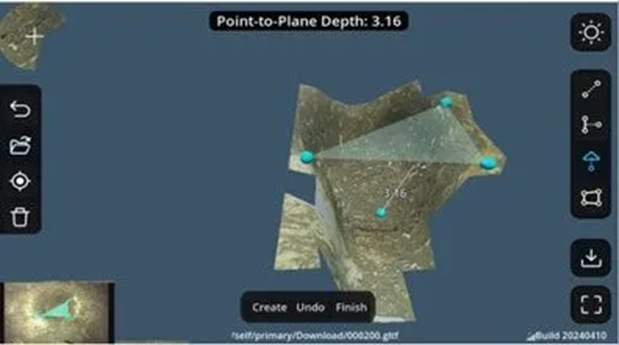

Why 3D Measurement Changes the Conversation

Traditional borescope inspections often produce strong visual documentation but limited quantitative data. Photos are useful, but images alone can struggle to answer the questions that matter most in decision-making:

- How long is the indication

- How deep is the defect

- How much surface area is affected

- How do measurements compare to prior inspections

3D measurement capability helps translate a visual finding into numbers that support maintenance actions. In practice, it can help teams distinguish between a superficial mark and material loss, between a surface feature and a true crack-like indication, and between a one-time event and progressive damage.

In regulated maintenance environments, the other benefit is consistency. Measurement-backed documentation is easier to review, easier to compare over time, and easier to defend during audits or technical reviews. It supports clearer communication between technicians, inspectors, and engineering teams, especially when multiple people need to interpret the same inspection evidence.

A Practical Dual View 3D Measurement Workflow

The USA3000J-6 is designed for inspection workflows where technicians need both imaging and measurement in one platform. When discussing dual view 3D measurement in the context of aircraft engines, it helps to think in terms of a repeatable sequence rather than a one-off capture.

A typical workflow looks like this:

- Plan the route and target areas

Before insertion, teams identify likely inspection points and expected access limitations. Knowing where the area of interest sits in the engine helps reduce time spent hunting. - Acquire a stable reference image

The first objective is clarity. That means controlling distance, stabilizing the tip, and managing glare. A clean reference image becomes the baseline for later comparisons. - Use dual view to confirm feature geometry

With a second viewpoint, technicians can check edges, transitions, and depth cues. Dual view is especially helpful on curved surfaces where one angle can hide the true shape of a defect. - Capture measurement-ready views

3D measurement works best when the view is stable and the defect is framed cleanly. The inspection goal shifts from simply seeing the indication to documenting it in a way that supports repeatable measurement.

For readers who want to review the configuration and positioning features that enable this workflow, the product page for the USA3000J-6 joystick articulation 6mm dual view 3D measuring videoscope provides a clear overview.

Where Dual View 3D Measurement Shines in Aircraft Engines

Dual view and measurement capabilities are valuable across the engine, but they become especially useful in areas where geometry is complex and the cost of uncertainty is high.

Compressor and fan sections

Fan and compressor components present a common challenge: highly reflective surfaces, leading edges that are easy to misread, and angles that change quickly as the probe moves. Small defects can look exaggerated when lighting catches an edge, and shallow dents can appear deeper due to shadowing.

Dual view helps technicians confirm what is happening at the edge and along the surface transition. 3D measurement helps turn the observation into a measurable description. That can support better decisions when determining whether a feature is within acceptable limits, whether it should be blended, or whether it warrants closer monitoring at the next interval.

Combustor and hot section views

Hot section inspection brings its own constraints. Space is tighter, surfaces may be discolored, and carbon deposits can complicate interpretation. When a feature looks suspicious, the challenge is often separating a surface condition from an actual defect that requires action.

Dual view can help assess whether an indication is continuous across a surface or simply a deposit pattern. When a defect is confirmed, 3D measurement can help quantify it in a way that supports consistent review. That matters when decisions involve costly downtime or when the maintenance team needs to document trends across multiple inspection cycles.

Vanes, blades, and shrouds

Vanes and shrouds often combine tight access with curved geometry. A single perspective can hide the real boundary of an affected area, particularly if the probe angle is not ideal. Dual view reduces the likelihood of missing the true edge of a defect.

3D measurement becomes particularly valuable when the affected area is irregular. Instead of relying on a rough estimate, technicians can document measurable dimensions and compare them to prior inspection records. Over time, that improves the quality of condition-based maintenance decisions and reduces unnecessary uncertainty.

Tips for More Repeatable Measurement Results

Even with a measurement-capable videoscope, technique still matters. A few habits consistently improve measurement reliability during engine inspections:

- Prioritize stability before precision

If the view is drifting or the tip is moving, capture quality suffers. Take an extra moment to stabilize before attempting measurement. - Manage reflections intentionally

Reflective surfaces can distort edges. Slightly adjusting the angle and lighting conditions often produces a clearer boundary. - Capture more than one measurement view

A second perspective is not just helpful, it is often the difference between a confident result and a questionable one. Dual view supports this naturally by giving more than one way to validate what the technician sees. - Do not force a measurement when the view is weak

If the defect edge is unclear, the best move is usually to reposition and recapture. A measurement that is fast but unreliable wastes time later during review.

These practices are especially important in aircraft maintenance, where the goal is not just capturing an image, but creating documentation that supports decisions across teams and across time.

Dual view imaging and 3D measurement capability can change the quality of aircraft engine inspections by reducing uncertainty and improving documentation. Instead of relying on a single angle and subjective interpretation, technicians can validate what they see and add measurable evidence to their findings. That supports better maintenance decisions, cleaner reviews, and fewer unnecessary re-inspections.

For teams evaluating inspection tools, USA Borescopes offers a range of options across the broader catalog and provides product-focused guidance for inspection needs. To learn more about USA Borescopes and to discuss which configuration best fits a specific inspection program, readers can also contact their team.

About The Author

The author is an independent inspection technology specialist with extensive experience supporting aviation maintenance teams. They focus on practical applications of videoscopes, measurement workflows, and inspection documentation standards. Their work emphasizes repeatable results, technician-friendly processes, and decision-ready evidence across turbine engine environments, without affiliation to any manufacturer.